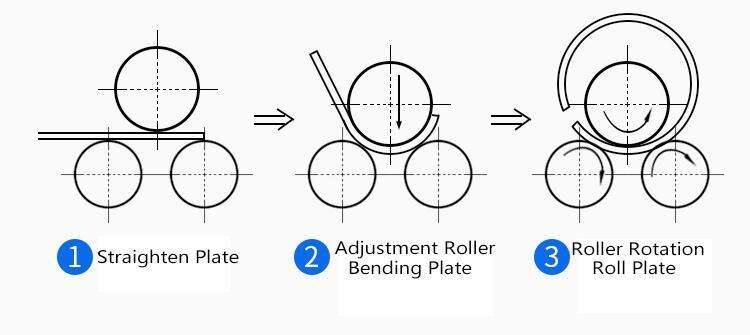

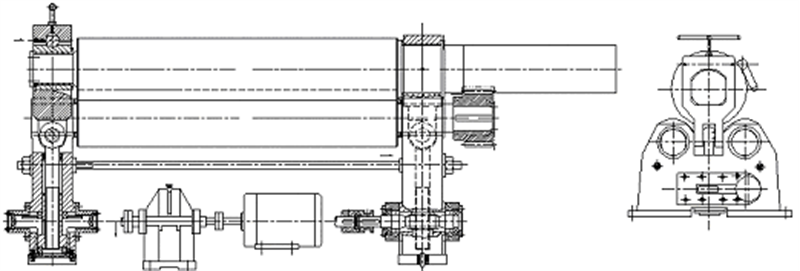

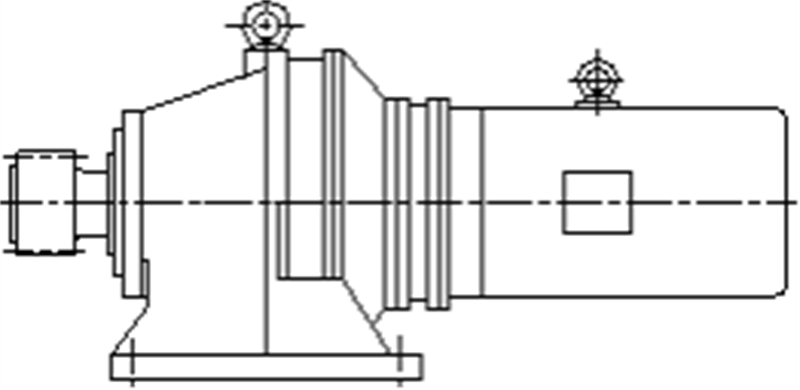

The structure of the machine is three-roll symmetrical, the upper roller in the middle of the two lower rollers symmetrical position for vertical lifting movement, through the screw worm drive to obtain the upper roller for lifting movement, through the reducer output gear meshing with the lower roller gear to obtain the two lower rollers for mutual rotation movement, to provide torque for the rolling plate. The machine is a whole structure, the working part and the main driving part are installed on a rigid welding base, which facilitates the installation and debugging of the machine.

|

Model |

Max. roll |

Max. roll |

Upper roller |

Bottom roller diameter - (mm) |

Central |

Main motor |

|

W11-6x1500 |

6 |

1500 |

160 |

160 |

220 |

4 |

|

W11-4X2500 |

4 |

2500 |

160 |

140 |

220 |

5.5 |

|

W11-6x2000 |

6 |

2000 |

170 |

150 |

250 |

5.5 |

|

W11-8x2500 |

8 |

2500 |

240 |

180 |

280 |

7.5 |

|

W11-10x2500 |

10 |

2500 |

250 |

190 |

320 |

11 |

|

W11-12x2500 |

10 |

2500 |

260 |

220 |

320 |

11 |

|

W11-16x2500 |

16 |

2500 |

280 |

240 |

360 |

11 |

|

W11-20x2000 |

20 |

2000 |

280 |

240 |

360 |

11 |

|

W11-25x2500 |

25 |

2500 |

370 |

280 |

480 |

22 |

|

W11-30x2000 |

30 |

2000 |

360 |

290 |

480 |

22 |

The two lower rollers are driving ones and the upper is an idler one. Upper roller do vertical elevating moving at the center position of two lower rollers, elevating of upper roller is realized through motor, speed reducer, worm gear and worm.

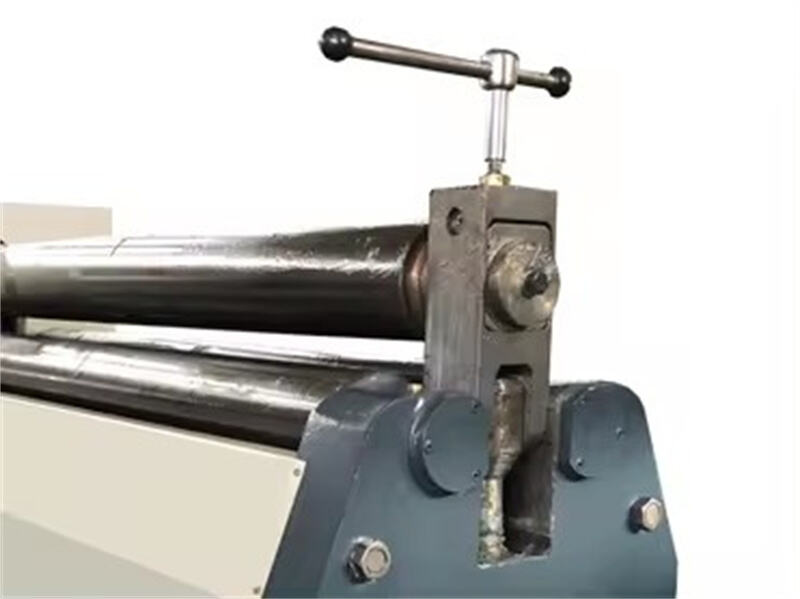

The manual drop end device is used when the cylindrical parts rolling are finished.

The transmission of the bottom roller is realized by the main motor through the main reducer.

This is composed of movable manipulation table and control box. the elevating distance of down roller can be displayed one manipulation table through photoelectricity coder.

This three-roller symmetric rolling machine carries out the reeling of cylinder work piece by the pressing of the top roller and the face-to-face rolling of the top and bottom rollers. It is mainly composed of the working unit, the driving unit, the balancing unit, the base and the cone unit, etc.

1. The Working Unit

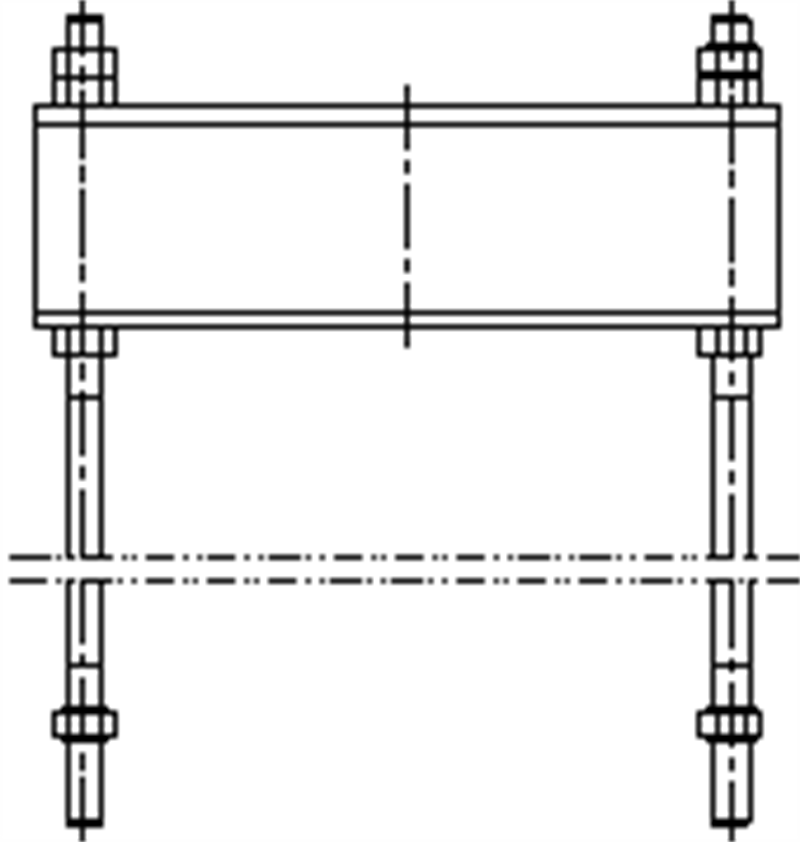

The working unit is composed of the bearing stand of the left and right rollers, one top roller, two bottom rollers, screw worm and worm wheel and some subsidiary parts.

The driving of the bottom rollers is carried out with the main motor through the main decelerator motor. The output bearing of the main decelerator is transmitted to the two bottom rollers through a set of gears. The change of transmission direction is obtained through the direction change of the main motor.

2.The Main Driving Unit

The main driving unit is composed of the main motor, the main decelerator motor and some subsidiary parts. The driving of the bottom rollers is carried out with the main motor through the main decelerator motor. The output bearing of the main decelerator is transmitted to the two bottom rollers through a set of gears. The change of transmission direction is obtained through the direction change of the main motor.

3. The Application of the Unloading Unit

When the cylinder work piece is complete, before taking it off the left bearing stand, make the top roller go up to its position, press the top roller at the rear with the balancing beam, and then pull out the shaft pin from the tapping bearing stand, tap down the bearing stand. The complete work piece goes off one side of the top roller.