Compared to traditional press brake machines, RAYMAX's specialization in hybrid technology development allows you to achieve at least 60% energy savings.

Our hybrid press brake machine reduces the demand for hydraulic oil and energy consumption, while also having an impact on bending performance.

1.Press brake adopts all-electric servo design precision folding bed, and has a high-rigidity and stable body design.

2.CNC press brake adopts high-speed back gauge and precision dual-servo motor spindle drive, which can achieve stable processing with high-speed precision.

3.Press brake can greatly save 60% of the power used, and there is no need to replace the oil and oil pressure valve regularly.

4.Press brake machine does not have the problem of oil temperature change affecting the machining accuracy, which can reduce the influence of thermal effect.

5.Electric press brake is suitable for rapid production of small samples and stable processing of a large number of high-speed and high-precision.

6.Press brake can be used in multi-stage continuous combined bending processing, which greatly improves production efficiency.

|

Type |

30T1250 |

40T1600 |

60T2000 |

70T2500 |

|

|

Nominal pressure (kn) |

300 |

400 |

600 |

700 |

|

|

Workbench length (mm) |

1250 |

1600 |

2000 |

2500 |

|

|

Poles distance (mm) |

1010 |

1360 |

1800 |

2100 |

|

|

Max Opening Height (mm) |

465 |

560 |

560 |

560 |

|

|

Throat depth (mm) |

300 |

300 |

350 |

350 |

|

|

Slider speed |

Rapid speed |

200 |

200 |

200 |

200 |

|

Return speed |

180 |

180 |

180 |

180 |

|

|

Return speed |

0-30 |

0-30 |

0-30 |

0-30 |

|

|

X-axis stroke (mm) |

450 |

450 |

500 |

500 |

|

|

R-axis stroke (mm) |

150 |

150 |

150 |

150 |

|

|

Weight (T) |

3.8 |

4.5 |

5.5 |

6.5 |

|

|

Dimensions L*W*H (mm) |

2000*1600*2490 |

2200*1600*2590 |

2700*1700*2690 |

3000*1700*2690 |

|

|

Motor (kw) |

2*12 |

2*12 |

2*24.1 |

2*24.1 |

|

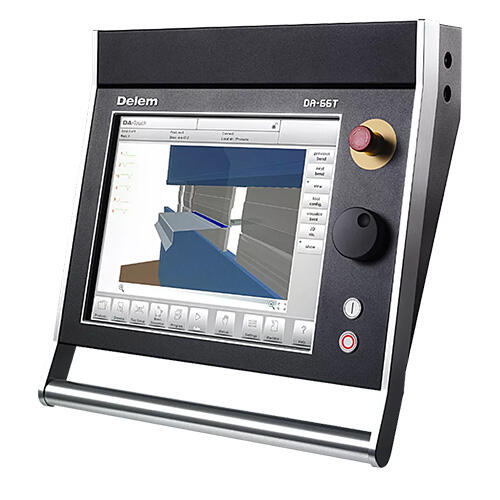

- CNC DELEM control system

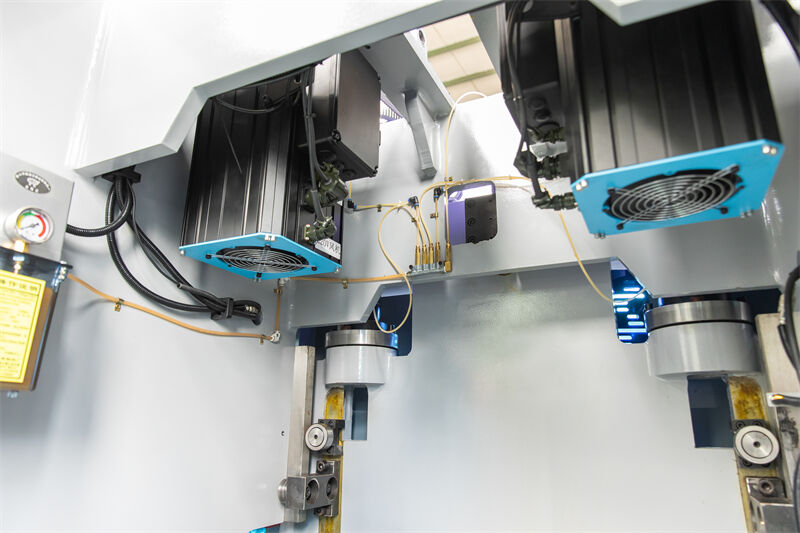

- INOVANCE Servo Motor

- Pump First USA brand

- Hydraulic Valve BOSCH-REXROTH Germany brand

- Foot Pedal Italy Pizzato brand

- Grating Ruler GIVI Italy Brand

- Electrical Schneider France brand

- Ball Screw& Linear guide Hiwin Taiwan brand

- Fast Clamping

- Light Curtain KELI brand (option)

- High precision: The bending accuracy of electric press brake machines is higher, with an error of only 0.01 millimeters per bending, suitable for high-precision and small-scale production.

- Low energy consumption: The electric system is very energy-efficient, only consuming power during the pressing process, with an energy efficiency of up to 90%.

- Environmental Protection: There is no risk of hydraulic oil leakage, and it will not cause pollution to the working environment, which meets the requirements of modern society for environmental protection.

- Easy to operate: No need for complex hydraulic debugging, operators can quickly get started and improve production efficiency.

- Easy maintenance: Low maintenance requirements, reducing downtime caused by equipment failures.

The choice between hydraulic press brake machine or electric press brake machine depends on specific production needs and environmental requirements. Hydraulic press brake machines perform well in handling large tonnage and high load tasks, while electric press brake machines have more advantages in energy conservation, environmental protection, and high-precision production.

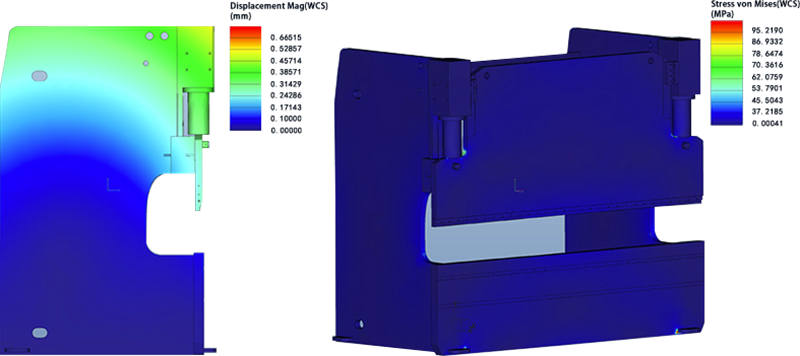

The machine body is in overall welded and overall processed structure, and ANSYS finite element analysis software is applied to main parts of the machine body for analysis, which has ensured the reliability of machine tool and the precision of entire machine. The foundation of every press brake is a solid, mono-block frame made from mill certified, high-yield steel. As a result our press brakes perform accurately and reliably year after year.

-10.1" high resolution colour TFT

-2D graphical touch screen programming

-“Hot-key” touch navigation

-Up to 4 axes (Y1,Y2 + 2 aux. axes)

-Profile-T offline software

- 15" high resolution colour TFT

- 2D graphical touch screen programming

- Up to 4 axes (Y1, Y2 + 2 aux. axes)

- Bend sequence calculation

- Profile-58TL offline software

- 17" high resolution colour TFT

- 2D graphical touch screen programming mode

- 3D visualisation in simulation and production

- Profile-T2D offline software

- 17" high resolution colour TFT

- 2D and 3D graphical touch screen programming mode

- 3D visualisation in simulation and production

- Profile-T3D offline software

- 24" high resolution color TFT

- 2D graphical touch screen programming mode

- 3D machine representation, in simulation and production

- Profile-SL offline software

- 24" high resolution color TFT

- 3D and 2D graphical touch screen programming mode

- 3D visualization, including 3D machine representation, in simulation and production

- Profile-S3D offline software

- 7” color graphic CRT screen

- 2D graphic profile creation with manual sequencing

- Up to 4 axes (Y1,Y2 + 2-axes)

- Angle and back gauge correction.

- Delivered with PC1200 offline software

- 12” color graphic with fully touch screen

- Touch 2D graphic part creation with manual sequencing

- Up to 4 axes (Y1, Y2, X, R-axes)

- Angle and back gauge correction.

- Delivered with PC-ModEva offline software

- 15” color graphic with fully touch screen

- Touch 2D graphical profile drawing and precise 2D program creation

- Up to 6 axes (Y1, Y2, X, R, Z1, Z2-axes)

- VisiTouch 2D or VisiTouch MX offline software.

- 10 inch LCD touch screen (Resistive)

- Touch 2D graphic part creation with manual sequence

- Stander to 4 axis(Y1, Y2, X, R)

- Free off-line PC simulation software

- Tandem machine management (option)

- Modbus TCP interface for SCADA or MES (option)

- 15 inch LCD touch screen (Resistive)

- Touch 2D graphic part creation with automatic sequence

- Stander to 4 axis, can up to 6 axis max.

- Free off-line PC simulation software

- Tandem machine management(option, can up to 4 machines)

- Modbus TCP interface for SCADA or MES (option)

- 18.5" designed for multi touch screen

- Support import of tools shapes (.dxf ifles)

- Support ESA 3D Bend software

- Equip standard industry 4.0 Modbus TCP interface

- 21.5” designed for multi touch screen

- Support multi touch application

- Support import of tools shapes (.dxf files)

- Support ESA 3D Bend software

- Equip standard industry 4.0 Modbus TCP interface

Using mechanical fast clamp for upper dies, changing dies more convenient and safe.

The transmission slider reciprocates, the output force is stable, the transmission precision is high, and the consistency of the bending pressure is guaranteed.

Movable front material support on linear guider can move left and right by hand very easy.

Using servo motor to drive the positioning axis, the mechanical structure is compact, the running speed is fast, the stability is high, and the repeated positioning accuracy is high.

- Replace the original Siemens motor

- Energy saving

- 40% power saving

- Noise reduction

- Fuel saving (smaller than ordinary fuel tank)

It is movable and can stop the machine anytime by the emergency button.

Be safer during machine operation

The tool cabinet on the side can also be used to store various tools.

DSP laser safety protection device comprehensively protects the personal safety of bending machine operators and avoids danger due to the rapid movement of the slider on the machine.