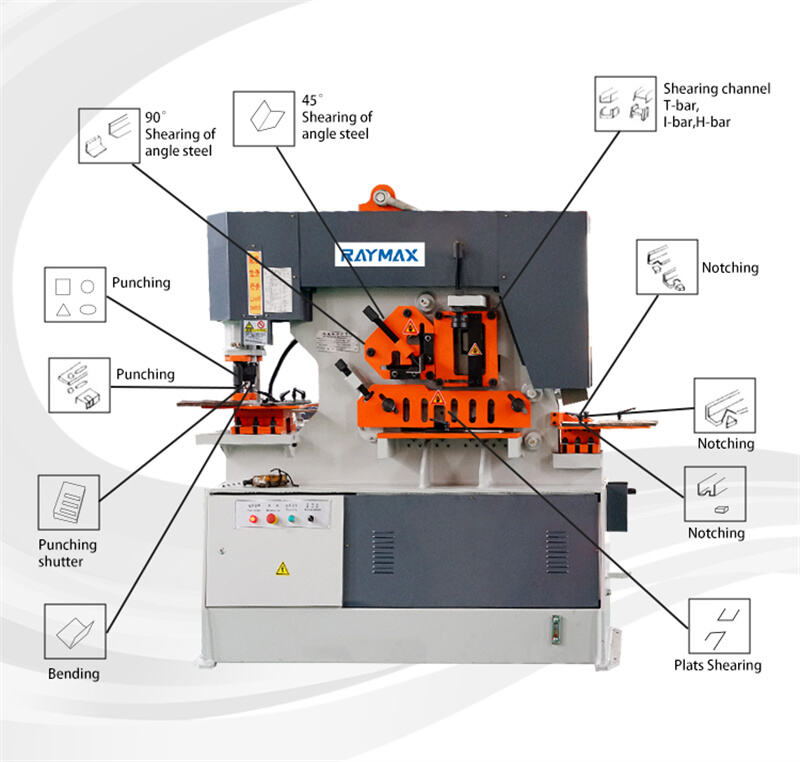

1. Q35Y Series industrial-grade hydraulic Iron Workers are featuring multiple functions, which includes: Punch, Angle Shear, Flat Shear, Round/Square Bar Shear. Notch, V-Notch, Channel Shear, Ι-beam Shear, T-bar Shear, Press Brake, Angle Bending and Pipe Notching. It comes standard with: quick-change coupling nut & sleeve, squaring arm with scale, electronic back gauge, gauging table with stops, punching base table, safety guards and more.

2. Hydraulic system: Adopt integrated hydraulic control system, more reliable and easy for maintenance. Hydraulic system is from Bosch Rexroth, Germany. All seals in cylinder is PARKER from USA, the most famous brand, good quality and high performance. Being able to work under rated load continuously, stable working and high precision.

3. Electrical components are from European, in accordance with international standards, reliable safety, long life, good anti-interference ability, a radiation unit is fitted in electrical cabinet. Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch, easy to operate. Emergency stops on machine and foot switch for safety, foot pedal conforming to CE regulation.

|

Model |

Q35Y-12 |

Q35Y-16 |

Q35Y-20 |

Q35Y-25 |

Q35Y-30 |

Q35Y-40 |

Q35Y-50 |

|

Punching |

35T |

60T |

90T |

115T |

145T |

200T |

250T |

|

Max.cutting thickness of |

12 |

16 |

20 |

25 |

30 |

40 |

50 |

|

Plate strength |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

≤450 |

|

Angle of Shear |

7 |

7 |

8 |

8 |

8 |

8 |

8 |

|

A trip size |

12x160 |

16×250 |

20×330 |

25×330 |

30×335 |

40×335 |

50×300 |

|

Trips frequency |

10-18 |

11-20 |

12-20 |

8-18 |

6-16 |

6-16 |

6-12 |

|

Throat depth (mm) |

115 |

300 |

355 |

400 |

600 |

530 |

600 |

|

Punch depth (mm) |

12 |

16 |

20 |

25 |

28 |

35 |

40 |

|

Max.punching diameter (mm) |

25 |

25 |

30 |

35 |

38 |

40 |

45 |

|

Main Motor Power |

4 |

5.5 |

7.5 |

11 |

15 |

18.5 |

18.5 |

|

Overall dimensions |

950×550 ×1800 |

1740×810 × 1830 |

1950×900 × 1950 |

2355×960 ×2090 |

2800×1050 ×2450 |

2900×1100 ×2500 |

3200×1440 ×2500 |

|

Profile |

Surface |

Q35Y-16 |

Q35Y-20 |

|

| Round Bar |

|

45 |

50 |

|

|

Square Bar |

|

40×40 |

50×50 |

|

|

Equal Angle |

90ºShearing |

|

120×120×12 |

140×140×12 |

|

45ºShearing |

50×50×5 |

70×70×10 |

||

|

T-Bar |

90ºShearing |

|

125×125×12 |

140×140×12 |

|

45ºShearing |

60×60×8 |

70×70×10 |

||

|

I-beam |

|

120×74×5 |

160×88×6 |

|

|

Channel |

|

120×53×5.5 |

160×63×6.5 |

|

|

Q35Y-25 |

Q35Y-30 |

Q35Y-40 |

Q35Y-50 |

|

|

60 |

65 |

70 |

80 |

|

|

50×50 |

55×55 |

60×60 |

65X65 |

|

|

160×160×14 |

180×180×16 |

200×200×18 |

200×200×18 |

|

|

60×60×6 |

80×80×8 |

80×80×10 |

100×100×10 |

|

|

160×160×14 |

180×180×16 |

200×200×18 |

200×200×18 |

|

|

80×80×10 |

80×80×10 |

100×100×10 |

120×120×12 |

|

|

200×102×9 |

280×124×10.5 |

300×130×13 |

200×102×9 |

|

|

200×75×9 |

280×86×11.5 |

300×89×11.5 |

320×92×12 |

|

1. Punching

Full range of universal punches and dies are available unique style allows for large angle iron punching and large channel.

Punching large viewing window on stripper swing away design for ease of operation large two piece gauging table with rulers and stop as standard fittings.

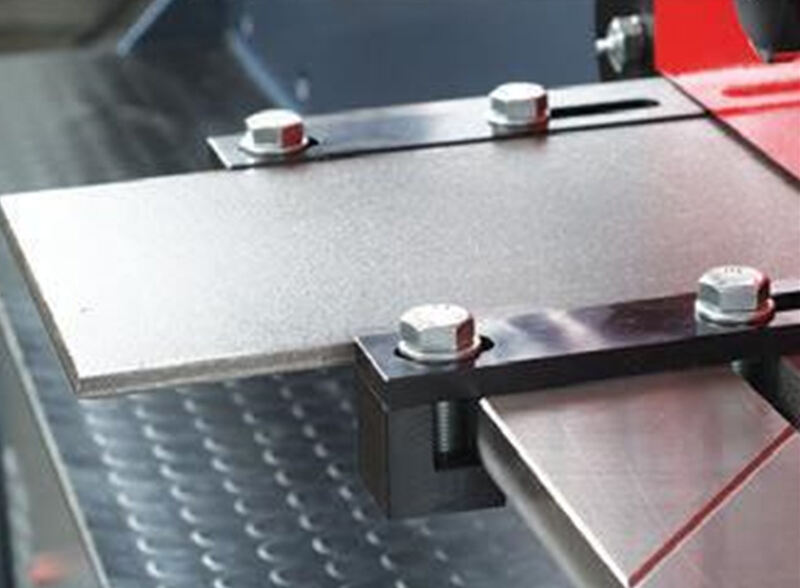

2. Shearing

Round and square bar shear has multiple holes for a variety of sizes. Adjustable hold down device for round/ square bar, channel/ beam cutting. Large strong guarding for max safely.

The angle shear has the ability to cut angle at 45 degree both top and bottom leg. This gives the operator the ability to make a picture frame Conner for perfect welds.

3. Notching

Unique design allows for cutting of angle and flat bar. Electrical interlock safety guard and three gauging stops for precise positioning.

4. Bending

Also bend the plate below 500 mm. All the components of machine are of the highest quality in their safety, function, capability and maintenance.

Customized special cutter plate can realize the cutting of special sections such as I-shaped steel and T-shaped steel

The stamping die can be customized according to the actual needs of customers

Equipped with Schneider electrical components, stable and reliable