No external cold water machine, equipment is small in size.

Convenient operation and outdoor welding can be realized.

Good beam quality, the high speed, small thermal deformation, high precision, highly integrated.

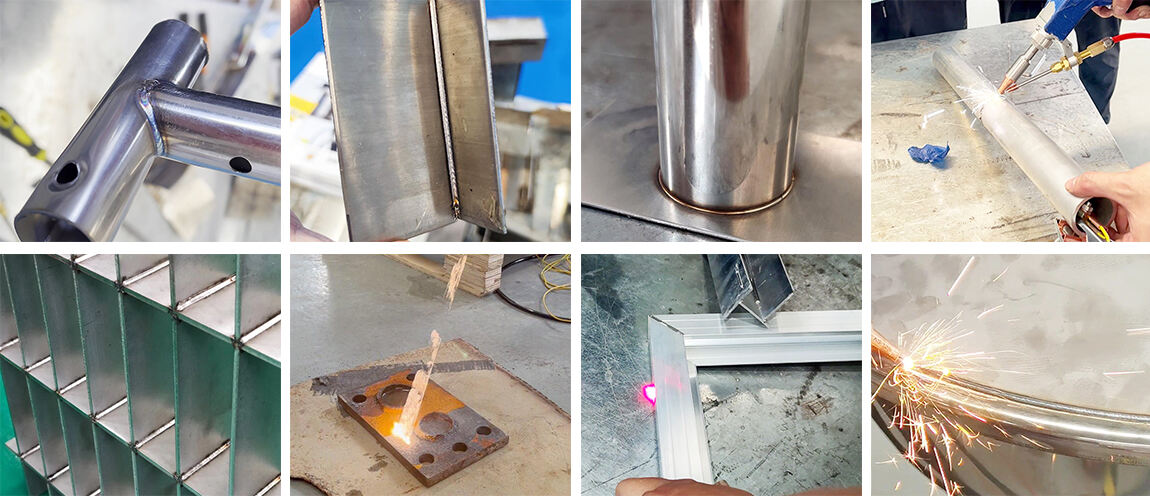

Handheld welding gun can achieve arbitrary Angle welding workpiece, applicable to complex welding and spot welding of various kinds of devices.

Weld beautifully, smoothly, without air hole, without treatment after welding or to be brief.

|

Model |

Hand-held fiber laser welding machine |

|

Power |

1000W 2000W 3000W (optional) |

|

Laser Wavelength |

1070NM |

|

Fiber Length |

Standard 10M / Maximum 15M |

|

Welding Speed |

0-120mm/s |

|

Cooling Method |

Industrial water chiller |

|

Working Temperature |

15-35℃ |

|

Recommend Welding Thickness |

0.5-3mm |

|

Voltage |

220V |

|

MATERIAL |

1000W |

1500W |

2000W |

|

Aluminium Alloy |

2.5MM |

3MM |

4MM |

|

Stainless Steel |

4MM |

5MM |

6MM |

|

Carbon steel |

4MM |

5MM |

6MM |

|

Galvanized |

2.5MM |

3MM |

4MM |

|

Brass |

3MM |

3.5MM |

4MM |

|

Mild Steel |

4MM |

5MM |

6MM |

|

Iron |

4MM |

5MM |

6MM |

Fast speed, good at thin plate welding, precision welding. Multiple nozzles optional

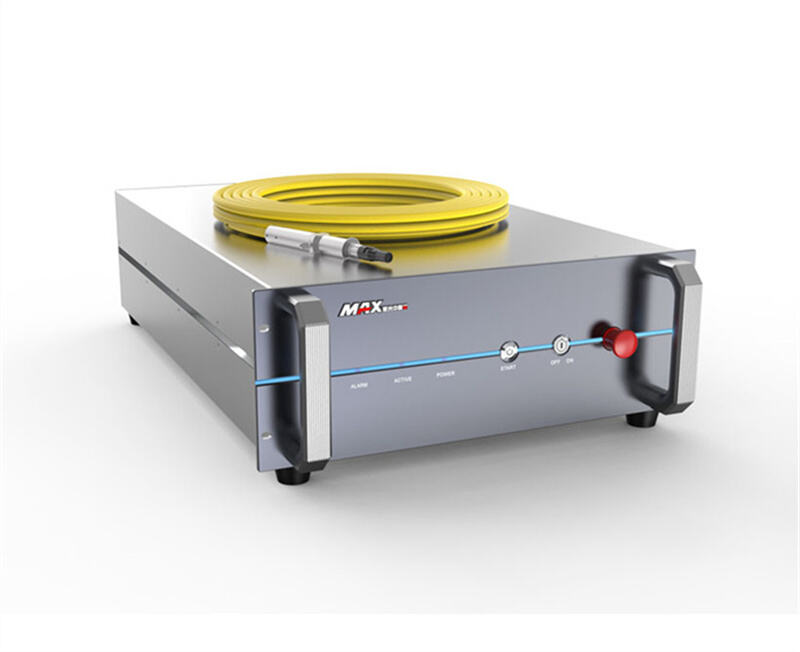

MAX, IPG, Raycus laser generator optional.

Stable laser power, long life, good welding effect, beautiful welding seam.

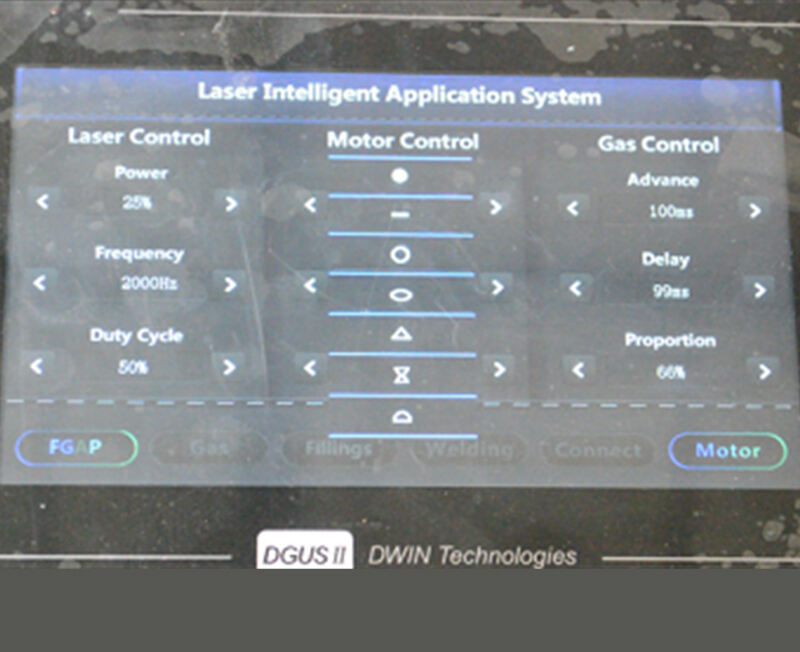

Display operation interface, simple and eye-catching button, no programming and teaching, simple operation.

High cooling rate, which can weld fine weld structure and good joint performance.

High degree of automation and labor cost saving.

Applicable Industries:

Can be widely used in cabinets, kitchen, staircase elevator, shelf, oven, stainless steel door and window guardrail, distribution box, stainless steel home and other industries complex and irregular welding procedures

Applicable Materials:

Materials that can be welded are extensive: cold work alloy steel, hot work alloy steel, nickel tool steel, steel alloy, high tenacity aluminum alloy, etc. Other metals like gold, silver, brass, aluminum-magnesium alloy, titanium, and platinum are also applicable.