1. Swing beam shearing machine adopts steel plate welding structure, hydraulic transmission, accumulator return, easy operation, reliable performance, and beautiful appearance.

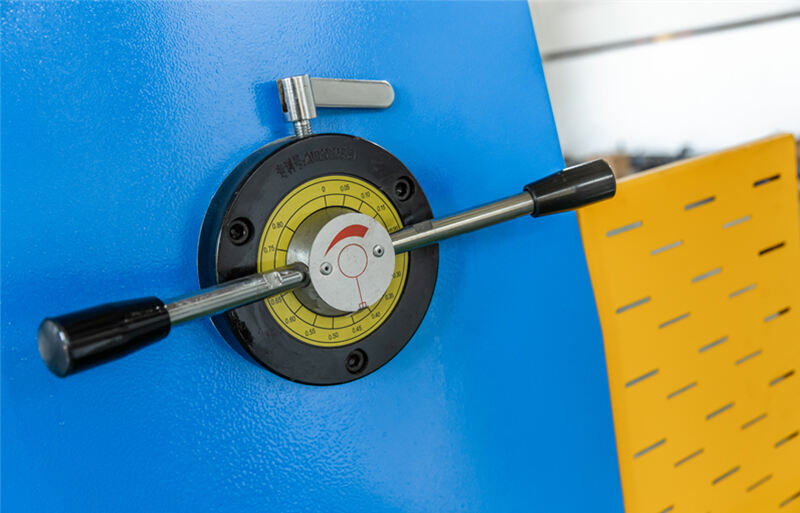

2. The adjustment of the cnc shearing machine blade gap is indicated by a signboard, making it easy and quick to adjust.

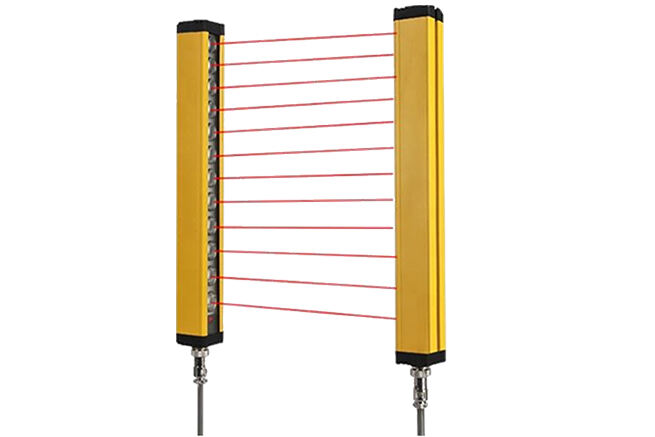

3. CNC metal shears use a fence style personal safety protection device.

4. With plate shearing machine, there is a digital display device for the size and cutting frequency of the rear stopper material.

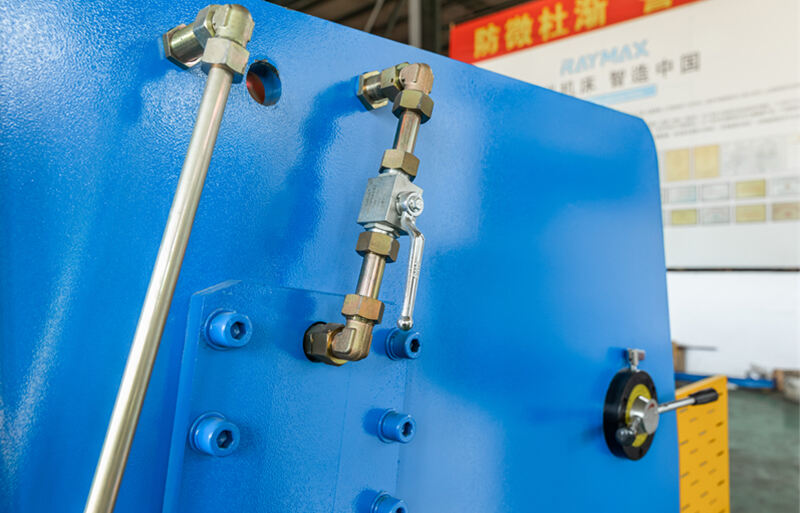

5. Metal shear machine with hydraulic transmission, swinging tool holder; Hydraulic metal shear adopts hydraulic integrated valve blocks from Bosch Rexroth, the compact structure reduces pipeline connections and improves system reliability and maintainability.

6. The overall welding of the hydraulic swing beam shearing machine frame is sturdy and durable, and the use of an accumulator oil cylinder for smooth and rapid return travel.

7. Hydraulic shearing machine has the function of infinitely adjusting the stroke, and the gap between the upper and lower blade edges can be adjusted with a handle, making shearing machine easy to adjust the uniformity of the blade gap.

8. The swing beam CNC shearing machine adopts an all steel welding structure, which eliminates stress through vibration and has good rigidity and stability. CNC shearing machine protective barriers and electrical interlocking ensure safe operation.

9. The CNC numerical control system and position encoder form a closed-loop control system, which has fast speed, high accuracy, good stability, and can accurately ensure the accuracy of the cnc shearing machine rear material displacement size. At the same time, the CNC system has multiple additional functions such as compensation and automatic detection.

| Model | Cutting thickness (mm) | Cutting length (mm) | Cutting Angel (°) |

Stopper Adjust Range (mm) |

Stroke time (min-1) |

Motor (KW) | Dimension (mm) | Weight (t) |

| QC12Y-4X2500 | 4 | 2500 | 1.5 | 500 | 18 | 7.5 | 2900x1500x1580 | 3.1 |

| QC12Y-4X3200 | 4 | 3200 | 1.5 | 500 | 14 | 7.5 | 3580x1500x1580 | 5.2 |

| QC12Y-4X4000 | 4 | 4000 | 1.5 | 500 | 12 | 7.5 | 4480x1500x1580 | 6.7 |

| QC12Y-6X2500 | 6 | 2500 | 1.5 | 500 | 18 | 7.5 | 2990x1650x1620 | 4.6 |

| QC12Y-6X3200 | 6 | 3200 | 1.5 | 500 | 14 | 7.5 | 3690x1650x1620 | 5.9 |

| QC12Y-6X4000 | 6 | 4000 | 1.5 | 500 | 12 | 7.5 | 4480x1850x1700 | 7.7 |

| QC12Y-6X6000 | 6 | 6000 | 1.5 | 500 | 12 | 11 | 6480x2000x2000 | 15.0 |

| QC12Y-8X2500 | 8 | 2500 | 1.5 | 500 | 18 | 11 | 2990x1700x1700 | 5.0 |

| QC12Y-8X3200 | 8 | 3200 | 1.5 | 500 | 14 | 11 | 3690x1700x1700 | 6.0 |

| QC12Y-8X4000 | 8 | 4000 | 1.5 | 500 | 12 | 11 | 4480x1850x1700 | 8.0 |

| QC12Y-8X6000 | 8 | 6000 | 1.5 | 500 | 12 | 15 | 6480x2000x2000 | 17.0 |

| QC12Y-10X2500 | 10 | 2500 | 2 | 500 | 14 | 15 | 2990x1700x1700 | 8.3 |

| QC12Y-10X3200 | 10 | 3200 | 2 | 500 | 14 | 15 | 3690x1700x1700 | 10.2 |

- Estun E21s NC control System

- Main Motor Siemens Germany brand

- Pump First USA brand

- Hydraulic Valve BOSCH-REXROTH Germany brand

- Ball Screw&Linear guide Hiwin Taiwan brand

- Foot pedal Pizzato Italy brand

- Electrical Schneider France brand

- Schneider PLC with Inverter

- Back gauge(X axis) movement control

- Control AC motor or inverter

- Intelligent and unilateral positioning

- Language for Chinese/English

- Cutting angle adjustment

Oil pump ensures long service life and reduce noise when working.

Rear pneumatic support system provides support and allows more precise cuts by keeping the material lifted throughout the cut, avoiding hanging down the wide and thin sheets.

Protect operator from dangerous operation.

Feeding the metal sheet automatically controlled by CNC Controller with high precision and efficiency.