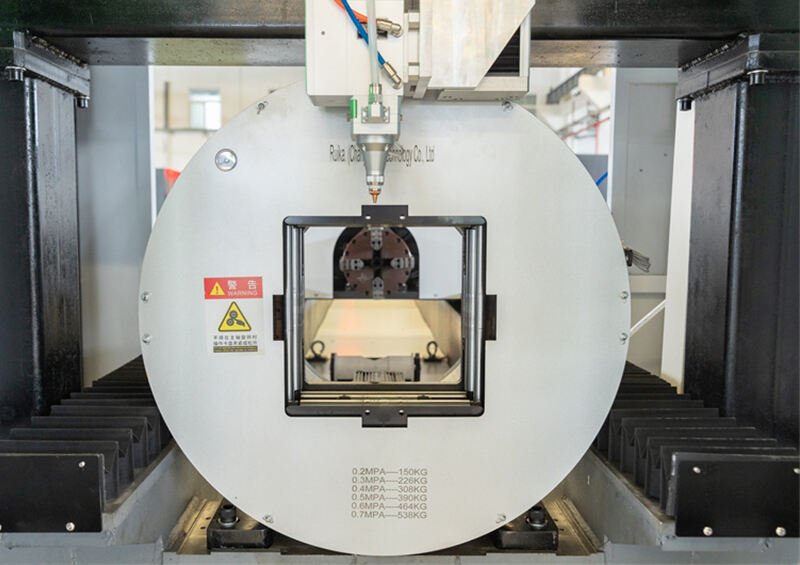

The plate and tube integrated fiber laser cutting machine adopts a cast iron bed, a rack and pinion drive system, and a professional cutting and cutting pipe of the CNC system, so that the user is easy to use and simple to operate and maintain. The machine is designed suitable for both sheet and pipe cutting.

Specially used for cutting 0.5mm-25mm carbon steel sheets and pipes: 0.5mm-10mm stainless steel sheets and pipes: galvanized steel sheets and pipes; electrolytic zinc-coated steel sheets and pipes; silicon steel sheets and pipes and other kinds of thin metal sheets and pipes. The pipes diameter is from 20mm-p200mm.

1. The plate and tube integrated laser cutting machine with fast cutting speed, good cutting quality, small cutting seam, small deformation, smooth, flat and beautiful cutting surface, without the need for post-processing;

2. Equipped with a pipe cutting device, it has a large working area and can cut flat and round pipes, making it more applicable and eliminating the cutting process. It is suitable for mass production, with high work efficiency and stable performance;

3. The tube plate integrated laser machine has high cutting accuracy and is more suitable for precision accessory processing and various fine handicraft cutting;

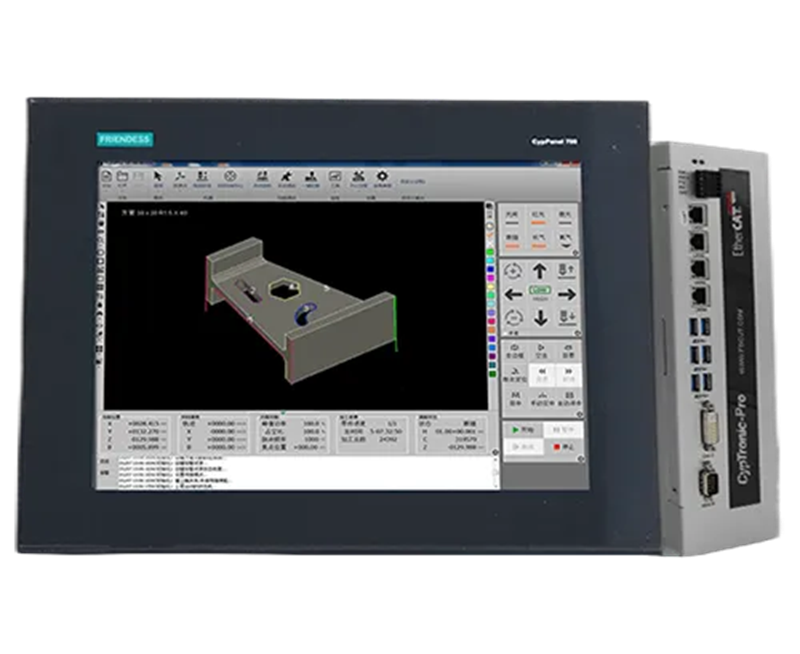

4. The perfect CNC system and professional auxiliary control software make work flexible, efficient, and machine operation simple and convenient.

5. The pipe and plate fiber laser cutting machine is equipped with a focal length automatic tracking and adjustment system, which can easily complete the cutting of twisted and deformed materials.

6. The entire laser cutting machine adopts imported servo motors and precision guide rails, which have high cutting accuracy, stability, and longer service life.

7. It can highlight its advantages in cutting pipes, with exquisite cutting technology and precise accuracy.

|

Product Model |

3015 |

4020 |

6020 |

6025 |

||

|

Working Area |

3000*1500mm |

4000*2000mm |

6000*2000mm |

6000*2500mm |

||

|

Laser Power |

1000W、1500W、2000W、3000W、6000W |

|||||

|

Positioning Accuracy |

±0.03mm/m |

|||||

|

Repeated Positioning Accuracy |

±0.02mm |

|||||

|

Voltage |

380VAC±10%/50Hz |

|||||

|

Cutting Pipe Performance |

3015GT |

4020GT |

6020GT |

6025GT |

||

|

Maximum Moving Speed |

120m/min |

|||||

|

Maximum Cutting Speed |

60m/min |

|||||

|

Drive System |

High precision gear and rack+high precision linear guide rail |

|||||

|

Plate Cutting Performance |

3015GT |

4020GT |

6020GT |

6025GT |

||

|

Pipe Dimension |

Circular tube 20~200mm/Square tube 20*20mm~150*150mm |

|||||

|

Processing Tube Type |

Round tubes,rectangular tube,elliptical tubes, U tubes etc. |

|||||

|

Maximum Pipe Length |

3000mm - 15000mm |

|||||

|

Fast Moving Speed |

30m/min |

|||||

|

Rotational Speed |

150r/min |

|||||

|

Drive System |

High precision gear and rack+high precision linear guide rail |

|||||

MAX Laser Generator

MFSC 10000W-12000W single module continuous fiber laser is a high-power fiber laser with high electro-optical conversion efficiency, compact size, good beam quality and maintenance free. It takes into account the high-speed cutting of thin plates and the bright surface cutting of medium and thick plates.

IPG Laser Generator

IPG fiber laser generator has reliable performance and low overall cost, which can help end users improve productivity while reducing costs. Full cutting capacity, metal plate cutting thickness up to 120mm.

|

RAYCUS Laser Generator |

|

| - High electro-optical conversion efficiency | - Customizable output fiber length |

| - QD connector | - Maintenance free operation |

| - Wide modulation frequency range | - Resistance to high inversion |

| - High efficiency in thin plate cutting |

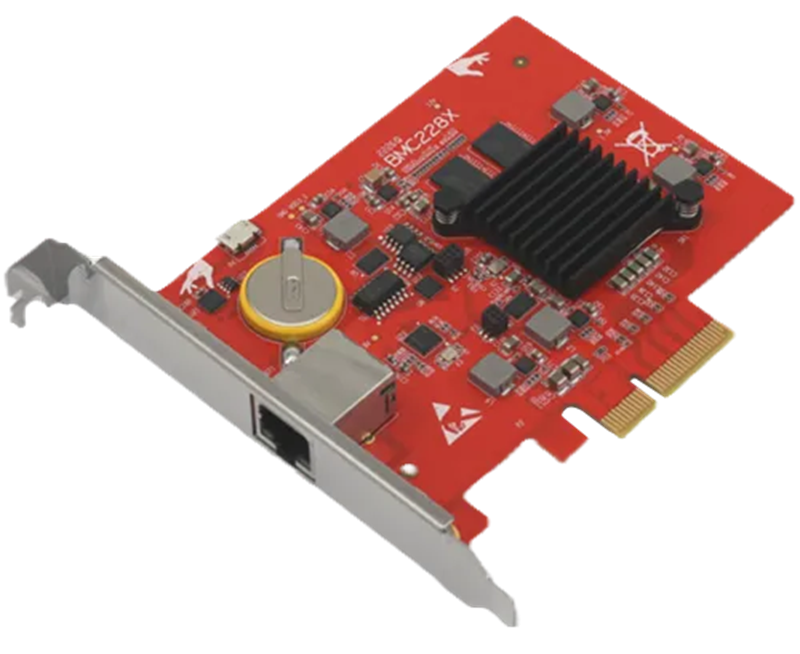

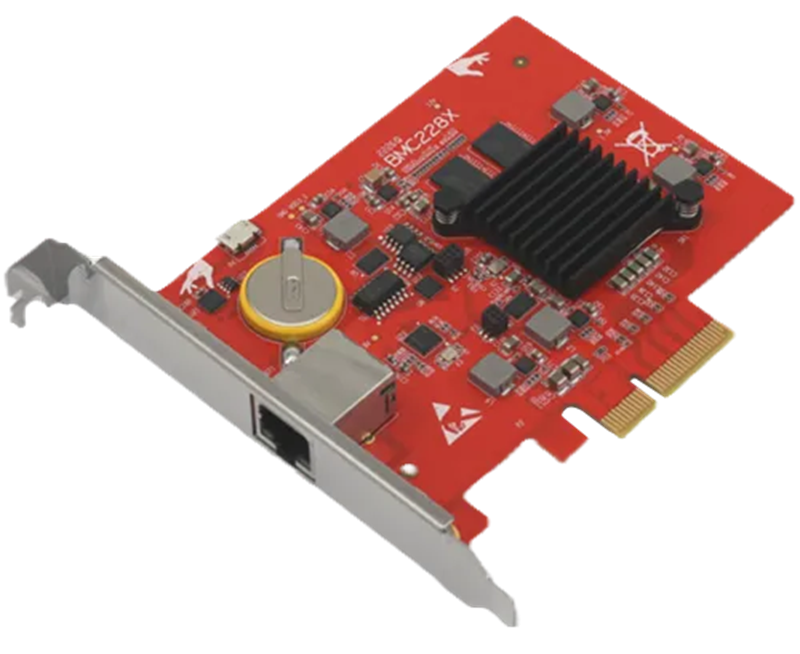

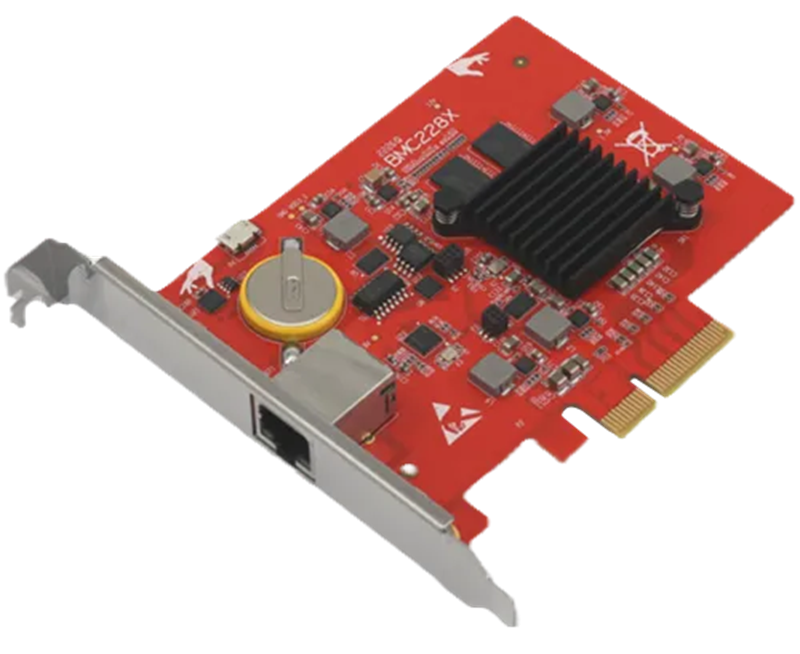

1000W-4000W EtherCAT System

Tube Laser Cutting System Support all functions of FSCUT2000 system

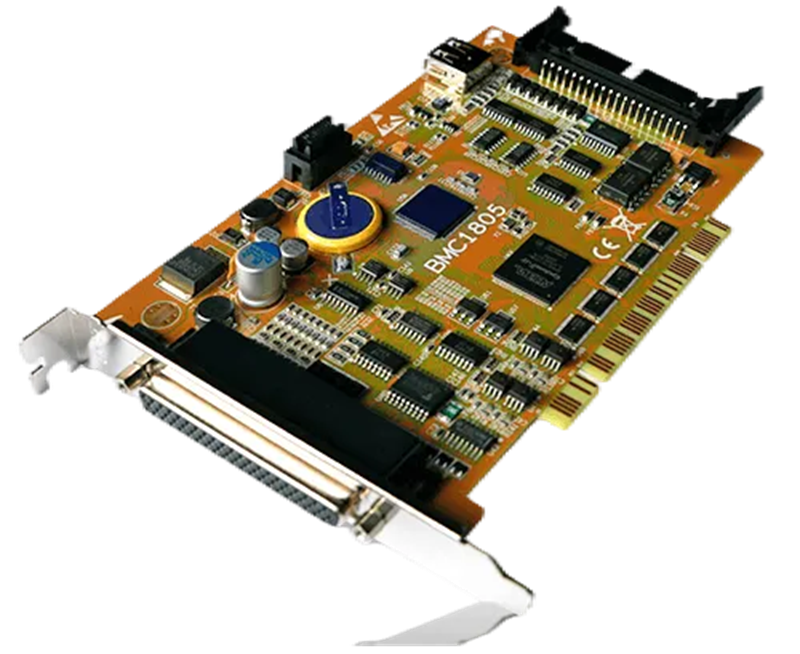

Medium Power EtherCAT System

Apply to 1.5-8KW power cutting

Tube Laser Cutting EtherCAT System

High Power EtherCAT System

Apply to 6-12KW power cutting

High Power Laser Cutting EtherCAT System

For ultra high power fiber laser above 8KW

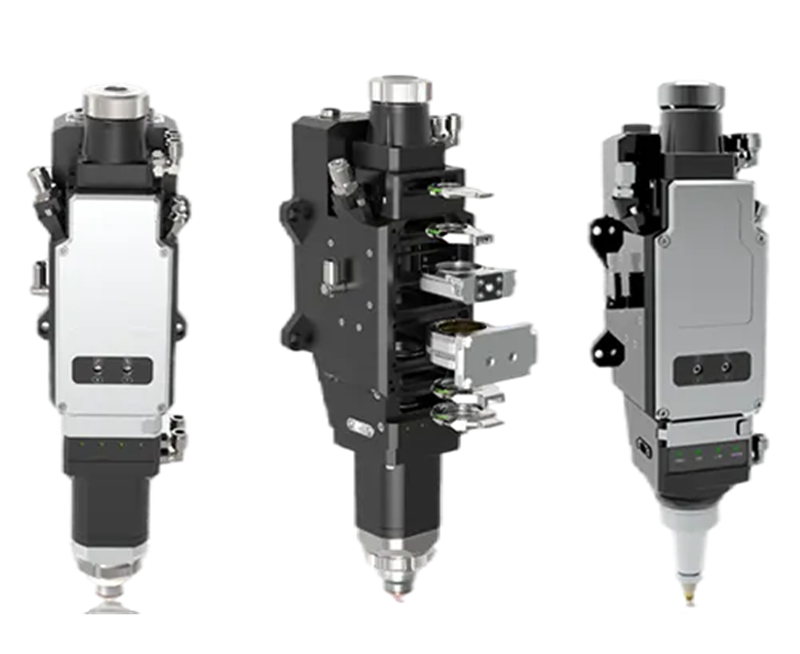

Low Power-RAYTOOLS Brand

Power rating 1.5KW

Power rating 3.3KW

Power rating 4KW

Power rating 6KW

High Power-BOCHU Brand

For power levels below 30KW

For high-power tube cutting

For ultra-high power laser equipment(max of 40KW)

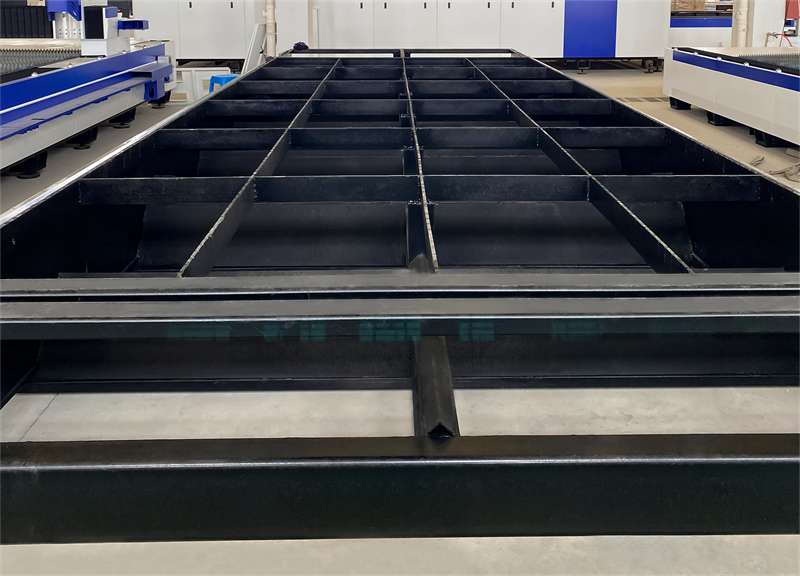

Steel plate welding workbench

Twice tempering

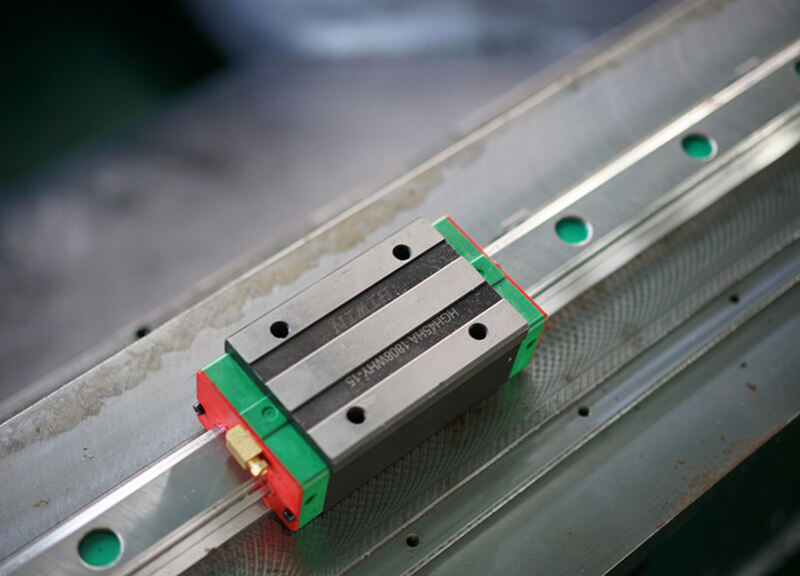

The combination of GERMAN ROR racks and TAIWAN HIWIN linear guides improves cutting speed

Optional linear guides brand: JAPAN SMG/ GERMAN HEREN

Adopt GERMAN Lead-motion or JAPAN FUJI servo motor with high performance and long service life.

Adopt GERMAN Lead-motion or JAPAN FUJI servo drive to ensure the stability and accuracy of work.

Adopting WuHan HanLi brand laser specific chiller

1. Equipped with dual control of high and low temperature water to meet the constant temperature requirements of the laser cavity and output port

2. Ensure the safe and stable operation of the laser

3. It has functions such as over temperature, flow rate, water level, real-time monitoring of water quality, sound and light alarm

France brand MOTOVARIO reducer. High tensile rigidity, high precision, low noise, ip65 protection level, to ensure the sustainable operation of 90 degrees.

The mechanical core transmission parts of the laser cutting machine, such as the guide rails and racks, are equipped with a fast lubrication system without blind spot. The control method of using equipment operation before refueling avoids the unevenness of static refueling, greatly improving lubrication efficiency and quality.

Gear transmission mode, higher transmission efficiency, long working life and high work reliability.

The laser cutting machine can cut most metal materials with a cutting thickness of up to 50mm.

Widely used in sheet metal processing, advertising sign production, high and low voltage electrical cabinet production, mechanical parts, kitchenware, automobiles, machinery, metal crafts, saw blades, electrical parts, glasses industry, springs, circuit boards, electric kettles, medical micro Electronics, hardware, knife measuring tools and other industries.