1.Hydraulic guillotine shearing machine adopts all EU streamlined design, manufactured with welding robot and stress relieving process.

2.Guillotine shear cutter is easy to maintain and more reliable with integrated hydraulic system, hydraulic system from Bosch Rexroth, Germany.

3.RAYMAX hydraulic shear has variable bevel action to adjust cutting length and load capacity according to different needs.

4.The guillotine metal shear backgauge distance is adjusted by motor and displayed by ELGO P40T servo motor.

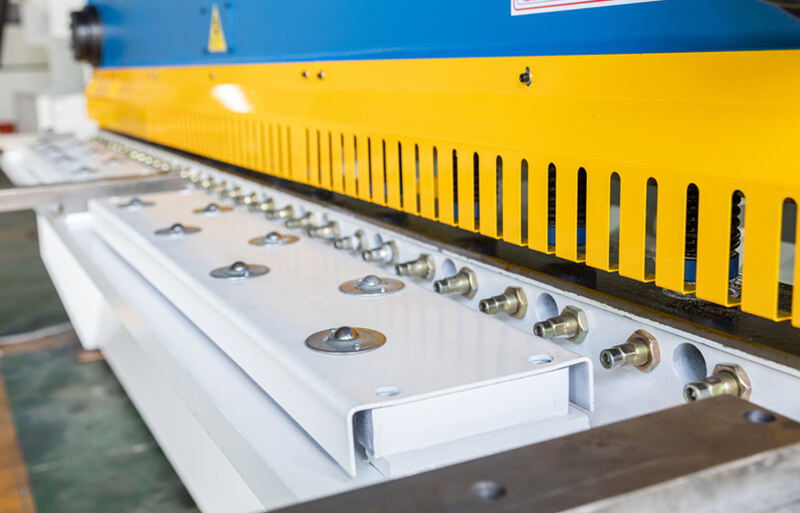

5.Automatic shearing machine is equipped with light alignment function for alignment during shearing and stepless knife beam stroke adjustment.

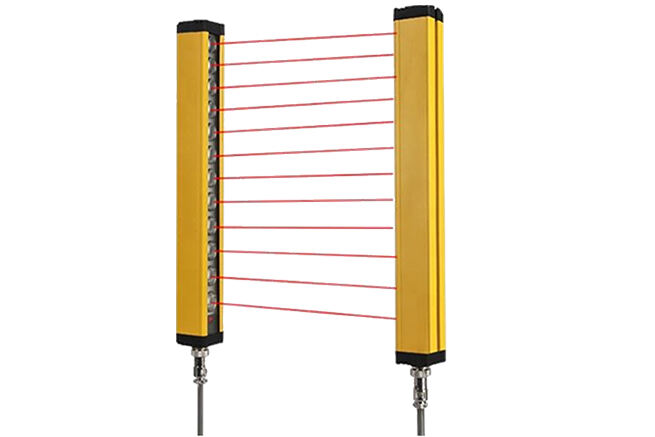

6.CNC hydraulic shearing machine is equipped with safety fence and electrical interlock, which complies with CE standards and ensures hydraulic metal shear safe operation.

|

Model |

Cutting thickness (mm) |

Cutting length (mm) |

Cutting Angel (°) |

Stopper Adjust Range |

Stroke time (min-1) |

Motor (KW) |

Dimension |

Weight |

|

QC11Y-6X2500 |

6 |

2500 |

0.5~1.5 |

500 |

20 |

7.5 |

2850X1800X1950 |

4 |

|

QC11Y-6X3200 |

6 |

3200 |

0.5~1.5 |

500 |

16 |

7.5 |

3450X1850X2000 |

5.2 |

|

QC11Y-6X4000 |

6 |

4000 |

0.5~1.5 |

500 |

12 |

7.5 |

4550X1850X2000 |

7 |

|

QC11Y-6X6000 |

6 |

6000 |

0.5~1.5 |

500 |

10 |

15 |

6940X2200X2450 |

11.5 |

|

QC11Y-8X2500 |

8 |

2500 |

0.5~1.5 |

500 |

18 |

11 |

2860X1850X2150 |

5 |

|

QC11Y-8X3200 |

8 |

3200 |

0.5~1.5 |

500 |

14 |

11 |

3460X1850X2150 |

6.2 |

|

QC11Y-8X4000 |

8 |

4000 |

0.5~2 |

500 |

12 |

11 |

4550X1750X1950 |

8 |

|

QC11Y-8X6000 |

8 |

6000 |

0.5~2 |

500 |

10 |

15 |

6940X2250X2550 |

14 |

|

QC11Y-10X2500 |

10 |

2500 |

0.5~2 |

500 |

15 |

15 |

2950X1850X2050 |

7 |

|

QC11Y-10X3200 |

10 |

3200 |

0.5~2 |

500 |

13 |

15 |

3650X1850X2050 |

8.3 |

|

QC11Y-10X4000 |

10 |

4000 |

0.5~2 |

500 |

12 |

18.5 |

4550X2050X2150 |

9 |

|

QC11Y-10X6000 |

10 |

6000 |

0.5~2 |

600 |

10 |

18.5 |

6850X2550X2650 |

17 |

- ELGO P40T CNC control System

- Main Motor Siemens Germany brand

- Pump First USA brand

- Hydraulic Valve BOSCH-REXROTH Germany brand

- Ball Screw&Linear guide Hiwin Taiwan brand

- Foot pedal Pizzato Italy brand

- Electrical Schneider France brand

- Schneider PLC with Inverter

- Large Color 7” LCD Touch Screen

- Auto Setting of Blade Clearance

- Auto Setting of Rake Angle

- User Program and Steps: Unlimited

It is derived from German brand motor, energy saving and environmental protection, low noise and stable performance.

Oil pump ensures long service life and reduce noise when working.

Rear pneumatic support system provides support and allows more precise cuts by keeping the material lifted throughout the cut, avoiding hanging down the wide and thin sheets.

Protect operator from dangerous operation.

Feeding the metal sheet automatically controlled by CNC Controller with high precision and efficiency.