High Precision End Pre-bending

End pre-bending allows adjustable straight edge length with high precision under specific pressure.

Superior Product Precision

Continuous bending and precise end pre-bending result in high-precision products. The upper roller's drum shape and adjustable supporting rollers ensure ideal results for both thin and thick plates.

NC Control for High Efficiency

Simplified operation and one-person handling significantly boost production efficiency.

Various Control Methods for Different Applications

- Control options include:

- TNC (Top NC): Small batch production

- T&BNC (Top & Bottom NC): Medium batch production

- CNC: High-volume, multi-variety production

Versatile Bending Shapes

- Supports various shapes:

- O-shape: Rear bending

- U-shape: Front bending

- Special bending: Combined methods.

|

Model |

Max. thickness of plate (mm) |

Thickness of pre-bending |

Max. width of plate (mm) |

Dia. of upper roller (mm) |

Dia. of lower roller (mm) |

Center distance |

Main motor power (KW) |

Hydraulic motor power (KW) |

|

W11S-8X2000 |

8 |

6 |

2000 |

235 |

Φ135 |

180 |

5.5 |

2.2 |

|

W11S-8X2500 |

8 |

6 |

2500 |

245 |

Φ145 |

200 |

7.5 |

4 |

|

W11S-12X2000 |

12 |

10 |

2000 |

255 |

Φ150 |

200 |

7.5 |

4 |

|

W11S-12X2500 |

12 |

10 |

2500 |

270 |

Φ150 |

245 |

11 |

5.5 |

|

W11S-12X3200 |

12 |

10 |

3200 |

300 |

Φ165 |

300 |

15 |

5.5 |

|

W11S-16X2000 |

16 |

12 |

2000 |

270 |

Φ150 |

245 |

11 |

5.5 |

|

W11S-16X2500 |

16 |

12 |

2500 |

300 |

Φ165 |

270 |

15 |

5.5 |

|

W11S-16X3200 |

16 |

12 |

3200 |

350 |

Φ180 |

300 |

15 |

7.5 |

|

W11S-20X2000 |

20 |

16 |

2000 |

300 |

Φ165 |

270 |

15 |

5.5 |

|

W11S-20X2500 |

20 |

16 |

2500 |

330 |

Φ180 |

300 |

15 |

7.5 |

|

W11S-25X2000 |

25 |

20 |

2000 |

350 |

Φ180 |

330 |

22 |

7.5 |

|

W11S-25X2500 |

25 |

20 |

2500 |

380 |

Φ200 |

360 |

22 |

11 |

|

W11S-30X2000 |

30 |

25 |

2000 |

380 |

Φ220 |

360 |

30 |

11 |

|

W11S-30X2500 |

30 |

25 |

2500 |

410 |

Φ235 |

380 |

30 |

11 |

|

W11S-30X3000 |

30 |

25 |

3000 |

450 |

Φ250 |

420 |

30 |

11 |

|

W11S-30X3200 |

30 |

25 |

3200 |

450 |

Φ250 |

420 |

30 |

15 |

|

W11S-30X4000 |

30 |

25 |

4000 |

560 |

Φ290 |

500 |

37 |

15 |

|

W11S-40X2000 |

40 |

35 |

2000 |

480 |

Φ250 |

420 |

37 |

22 |

|

W11S-40X2500 |

40 |

35 |

2500 |

500 |

Φ275 |

460 |

45 |

22 |

|

W11S-40X3000 |

40 |

35 |

3000 |

540 |

Φ290 |

500 |

55 |

22 |

|

W11S-40X4000 |

40 |

35 |

4000 |

610 |

Φ360 |

610 |

75 |

22 |

|

W11S-50X3200 |

50 |

40 |

3200 |

650 |

Φ360 |

700 |

75 |

22 |

|

W11S-50X4000 |

50 |

40 |

4000 |

700 |

Φ380 |

700 |

75 |

22 |

|

W11S-60X3000 |

60 |

50 |

3000 |

650 |

Φ380 |

700 |

75 |

22 |

The machine consist of upper lower equipment, lower equipment and horizontal shift equipment, supporting equipment, main transmission equipment, reversing equipment, left and right side frame and the bottom support etc.

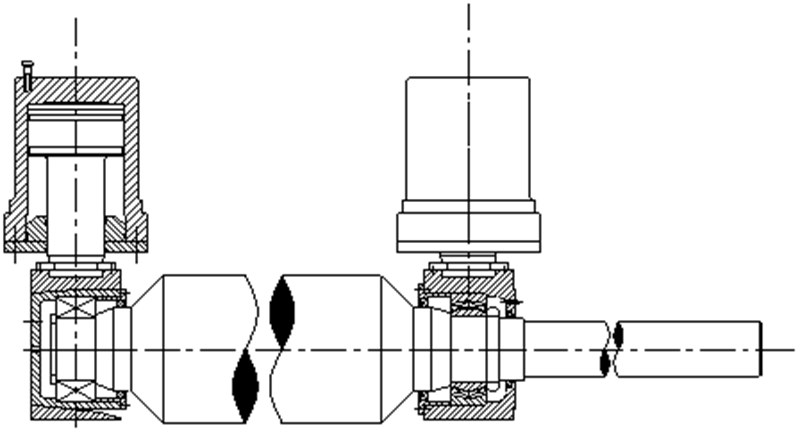

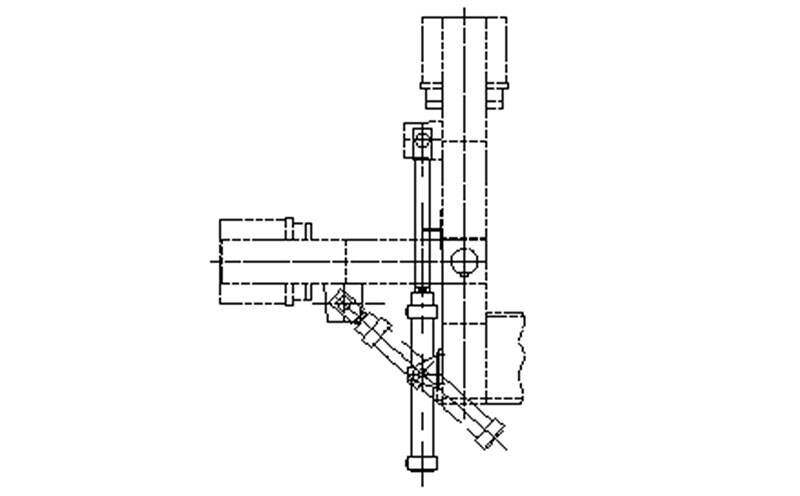

1. Upper-roll equipment

It’s consists of main cylinders, upper roller bearing seats, the two main oil cylinders supply the needed bending force, the working force of main cylinder is 19.5MPa, the upper roller looks like drums.

The material is 42CrMo,and the hardness is HB260-300, HRC45.

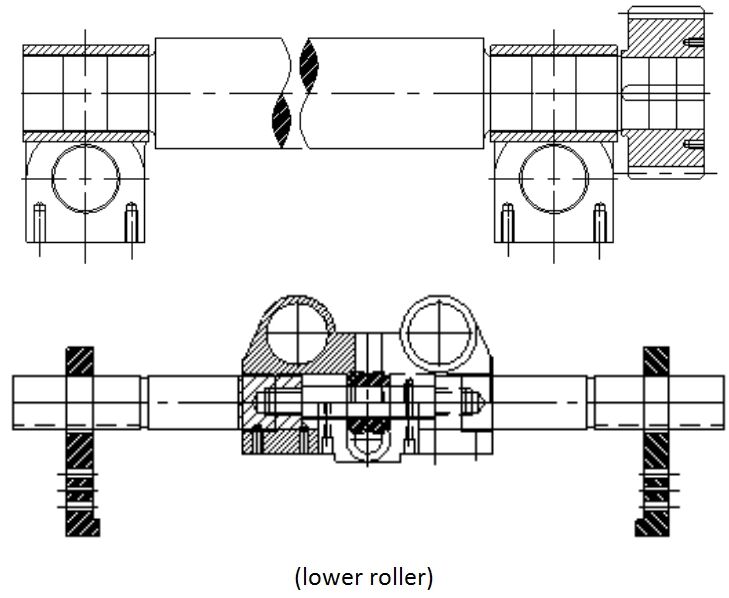

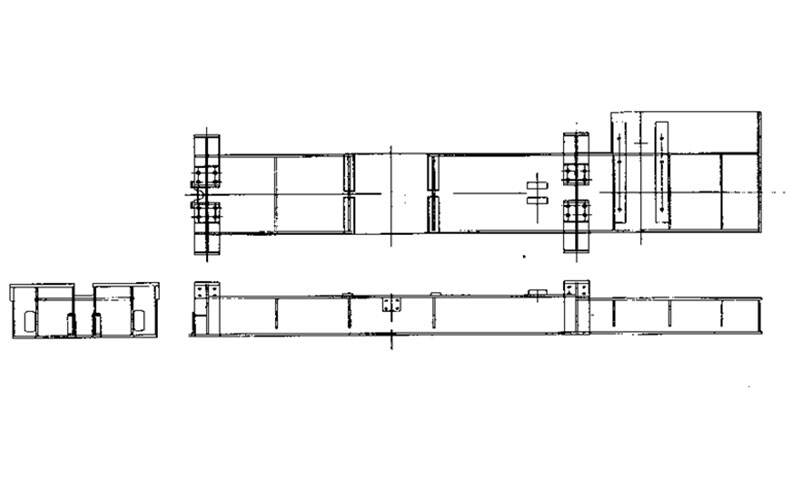

2. Lower rollers and horizontal shift equipment

The lower rollers is consisted of lower rollers, lower rollers bearing seats, lower roller input gears, lower roller sliding bearing, etc.

The horizontal shift equipment drove by horizontal shifting motor, via the worm reducer. Worm wheel and worm bar also ball screws realize the function of symmetry rolling.

The lower main motor supply the power to the lower rollers via the main transmission gear, lower roller input gear, open-type transmission shaft.

The horizontal shaft equipment consist of: horizontal shifting motor, worm gear traducer, worm gear and worm bar, etc.

The material is 45#, and the hear treat hardness HB260-300, HRC45.

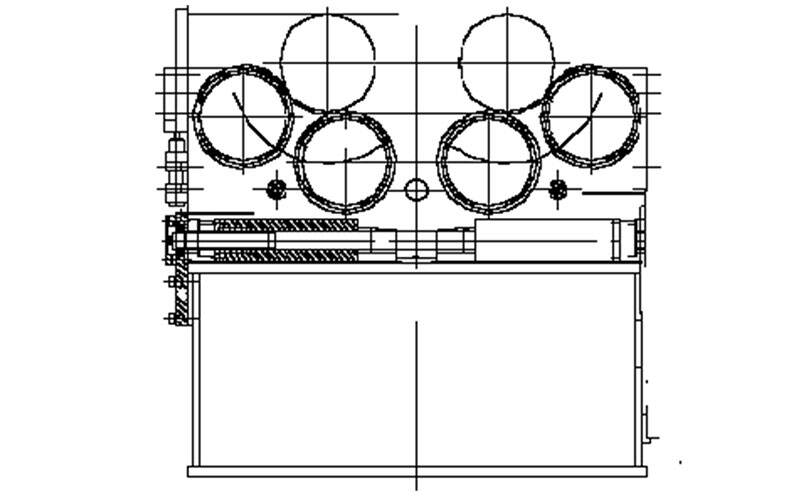

3. Supporting roller equipment

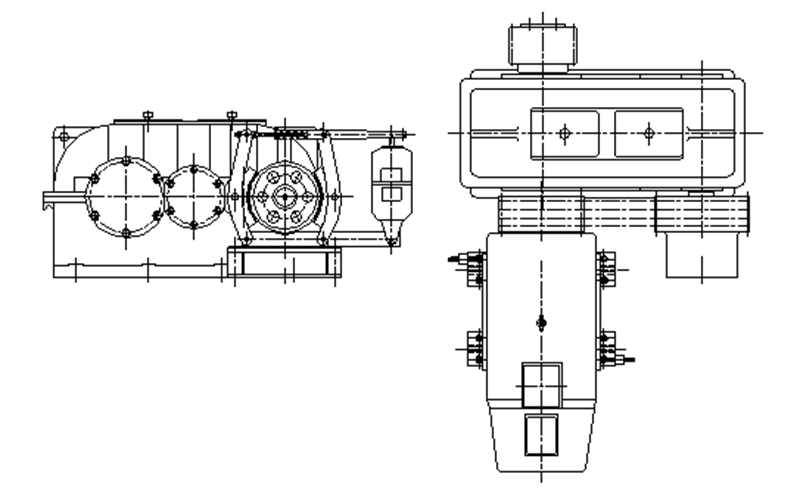

4. Main transmission equipment

Consist of main motor, V-belts, gear reducer, electro-hydraulic braking, etc.

5. Unloading equipment

6. Fixed, unlied-side frame, bottom frame

- Consist of gear pump, Solenoid station, and the pipes circuits.

- The solenoids made in Tai Wan.

- The hydraulic system consists of 3 kinds of circuit, pressure adjusting circuit, symmetry circuit, speed circuit, etc.

- The pressure adjusting circuit adjusting the working pressure by main overflow valves, the system working pressure is 19.5MPa. Symmetry circuit can made the upper roller up & down by adjusting the throttle, and the symmetry accurate is +0.20mm.

- The speed circuit control the unload side frame traversing and re-set, and the speed can be adjusted by the throttle.

It consists of electro-control-station(box), manual-handed bottom station, power source is 380V/50Hz.

The main switch has the functions of short-circuit protection and the main motor over-loaded protection function. The motor directions can be controlled by A.C contactor, the control circuit controlled by PLC controller and the Touching Screen-Inter face system. The symmetry precession is very high, with the reliable action, and long life. All control buttons indicators are fixed is the Electrical-control-box.