The press brake can be equipped with a variety of models of specialized CNC systems: E21, E310, CT8, and so on;

With multi-step programming function, nc press brake is able to realize automatic execution and continuous positioning of multi-step program, and realize automatic adjustment of backstop material and slider position;

Beding counting, real-time display of the number of processing, power failure memory backgauge slider position, program and parameters;

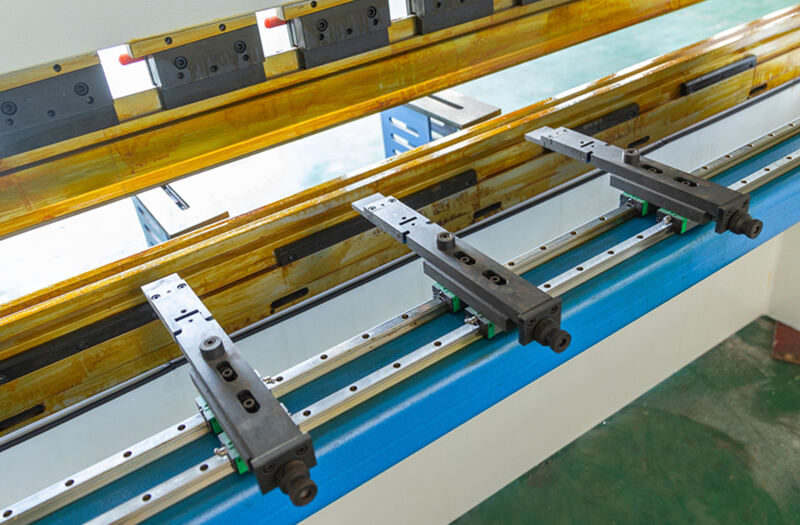

Backgauge adopts imported ball screw and linear guide, which ensures the positioning accuracy of the backgauge and higher machine processing precision.

Adopting torsion bar synchronization, mechanical blocking, reliable, economical and high precision.

The distance of backgauge and the stroke of upper slider are automatically adjusted by CNC system, and can also be manually adjusted for easy operation.

| Type | Nominal pressure (KN) | Workbench length (mm) | Workbench width (mm) | Poles distance (mm) | Throat depth (mm) | Main motor (kw) | Dimensions L*W*H (mm) |

| 50*2500 | 500 | 2500 | 800 | 1900 | 250 | 5.5 | 2500*1250*2000 |

| 63*2500 | 630 | 2500 | 850 | 1900 | 320 | 5.5 | 2500*1500*2200 |

| 63*3200 | 630 | 3200 | 850 | 2600 | 320 | 5.5 | 3200*1500*2200 |

| 80*2500 | 800 | 2500 | 850 | 1900 | 320 | 7.5 | 2500*1600*2270 |

| 80*3200 | 800 | 3200 | 850 | 2600 | 320 | 7.5 | 3200*1600*2270 |

| 100*2500 | 1000 | 2500 | 850 | 1900 | 320 | 7.5 | 2500*1700*2420 |

| 100*3200 | 1000 | 3200 | 850 | 2600 | 320 | 7.5 | 3200*1700*2420 |

| 100*4000 | 1000 | 4000 | 850 | 3100 | 320 | 7.5 | 4000*1700*2420 |

| 125*2500 | 1250 | 2500 | 850 | 1900 | 320 | 7.5 | 2500*1750*2450 |

| 125*3200 | 1250 | 3200 | 850 | 2600 | 320 | 7.5 | 3200*1750*2450 |

| 125*4000 | 1250 | 4000 | 850 | 3100 | 320 | 7.5 | 4000*1750*2450 |

| 160*2500 | 1600 | 2500 | 900 | 1900 | 320 | 11 | 2500*1800*2700 |

| 160*3200 | 1600 | 3200 | 900 | 2600 | 320 | 11 | 3200*1800*2700 |

| 160*4000 | 1600 | 4000 | 900 | 3100 | 320 | 11 | 4000*1800*2700 |

| 160*6000 | 1600 | 6000 | 900 | 5000 | 320 | 11 | 6000*1900*2700 |

| 200*3200 | 2000 | 3200 | 900 | 2600 | 320 | 11 | 3200*2000*2700 |

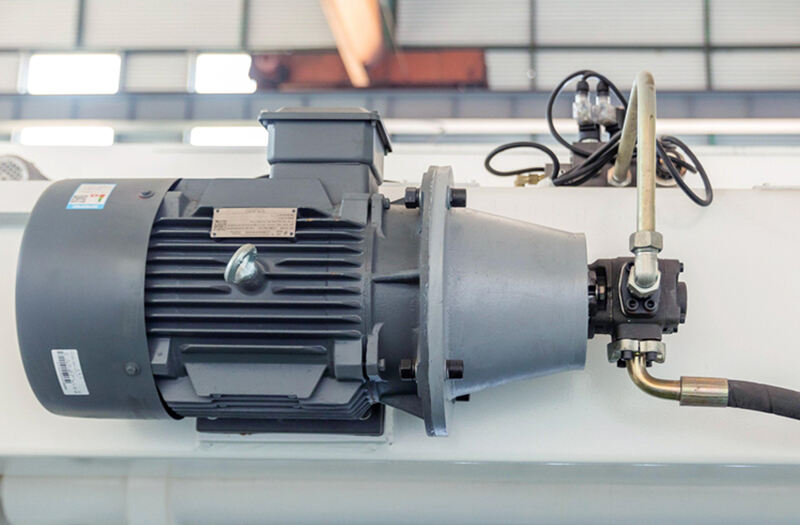

- Main Motor Siemens Germany brand

- Pump First USA brand

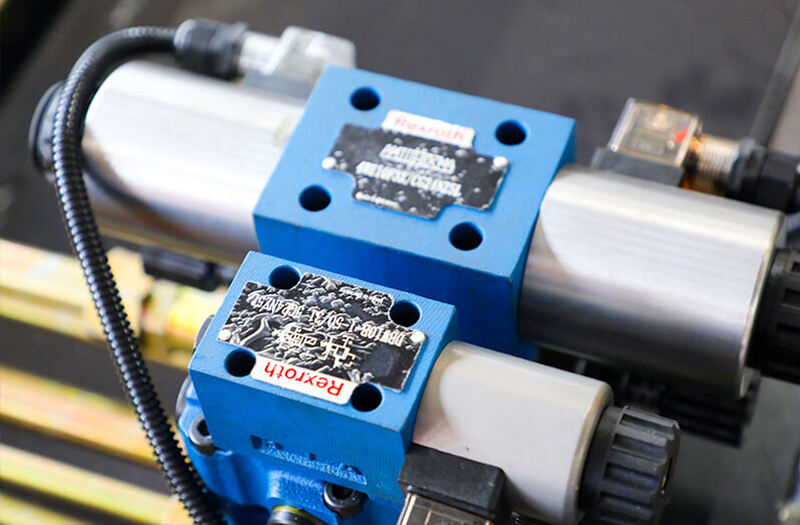

- Hydraulic Valve BOSCH-REXROTH Germany brand

- Foot Pedal Italy Pizzato brand

- Electrical Schneider France brand

- Ball Screw& Linear guide Hiwin Taiwan brand

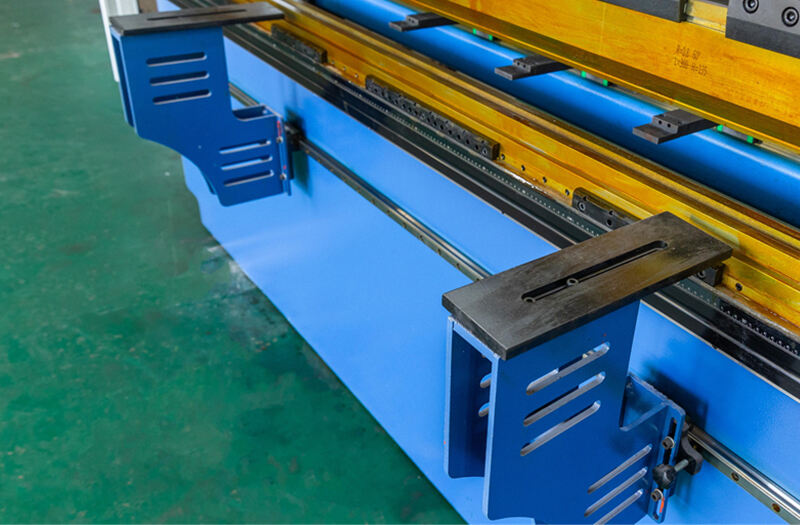

- Fast Clamping

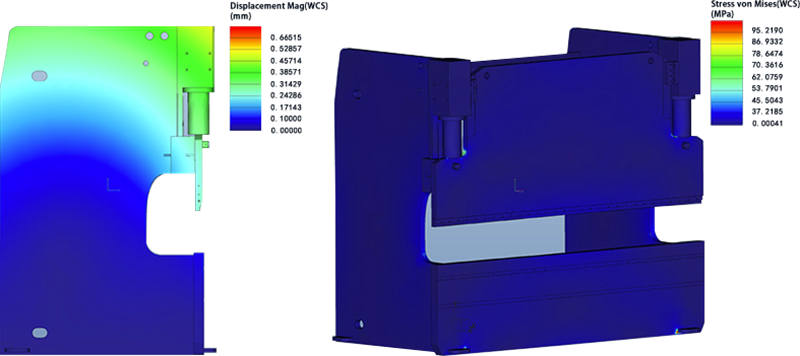

The machinery frame features a fully-welded and processed construction, with ANSYS finite element analysis employed for assessing the principal components of the frame, thereby guaranteeing the dependability of the machine and its overall accuracy. Each press brake is built upon a robust, one-piece foundation fabricated from premium-grade, high-strength steel, ensuring that our press brakes deliver consistent and trustworthy performance annually.

Dual hydraulic cylinders on either side of the ram provide faster approach speeds. Cylinders are synchronized to provide smooth motion, resulting in accurate ram positioning to within 0.004".

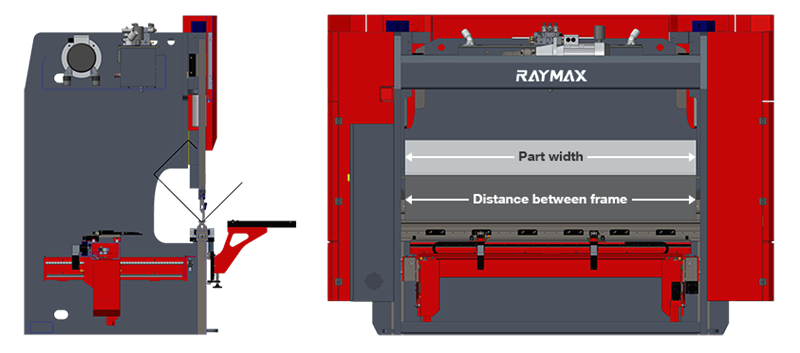

RAYMAX press brakes can easily handle parts with deep bends and long tooling due to their open space design. Our machines typically have deeper throat depths, greater daylight clearance and longer stroke lengths than most manufacturers on the market. We mount the RAM GUIDING on the outside of the frame to maximize the distance between the side frames to accommodate deep part flanges.

- High-definition LCD screen

- Supports bilingual Chinese and English

- Intelligent positioning of X and Y axes supports manual adjustment

- X,Y and R servo axes controlled by CAN bus

- Crowing supports both mechanical and hydraulic modes

- Built in machine work logic, multiple work modes

- Tools library and material table

- I / O ports are freely configurable

- Panel based housing

- Bright LCD screen

- Beam stop control (Y)

- Backgauge control (X)

- Retract functionality

- 7” color graphic CRT screen

- 2D graphic profile creation with manual sequencing

- Up to 4 axes (Y1,Y2 + 2-axes)

- Delivered with PC1200 offline software

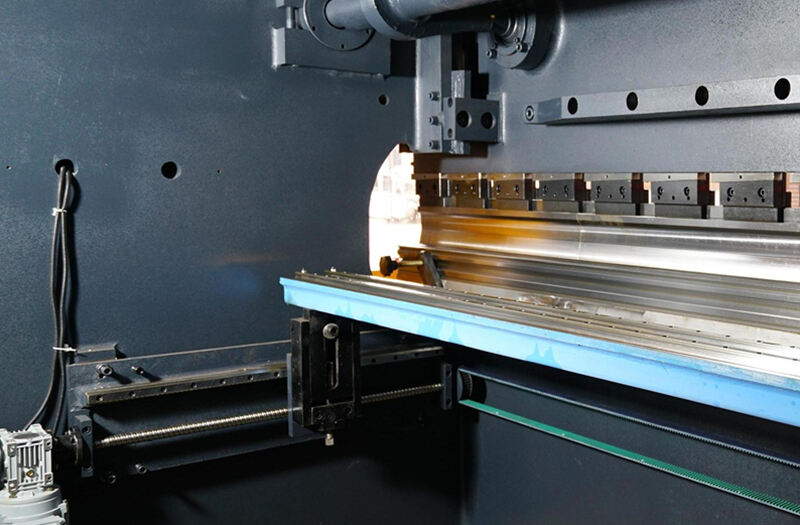

Our machines feature a rear stop assembly that is independently designed with high precision, equipped with HIWIN high-precision ball screw, adjustable stop finger, and manual lifting capabilities. This design enables our machines to adapt to a variety of different punches.

Hydraulic transmission with high reliability, integrated hydraulic system can effectively alleviate problems caused by leakage of hydraulic fluid. The hydraulic system pressure can be adjusted to suit specific practical needs, enabling it to meet the bending force requirements.

We offer Germany brand SIEMENS motor, offering high efficiency, energy-saving capabilities, large starting torque, excellent performance, low noise and vibration, and exceptional reliability.

We have the capability to customize the power and voltage of our machines to match the specific voltage requirements of our customers' local regions.

The fast clamp is convenient and efficient, which can greatly improve the efficiency in the process of assembly line operation.

Movable front material support on linear guider can move left and right by hand very easy.

The appropriate V-shaped opening width can be selected according to the bending thickness, and it can also be used with semi-circular notches.

The mechanical compensation worktable is an effective solution to eliminate the impact of ram deformation on bending accuracy. This is achieved by adjusting the bulge at each position in the middle through either multi-point compensation worktable or manual deflection compensation worktable. Additionally, it can also rectify angle errors at different positions within the workpiece.

The stop finger can move smoothly on the linear guide and can be adjusted up and down, which is convenient, efficient and easy to control.

Italy PIZZATO brand foot switch is movable and can stop the machine anytime by the emergency button.

Adopt steel torsion bar synchronization system with high accuracy . At the 2 ends of the ram, there are 2 synchronizing devices so that the ram movement is always parallel to the worktable.